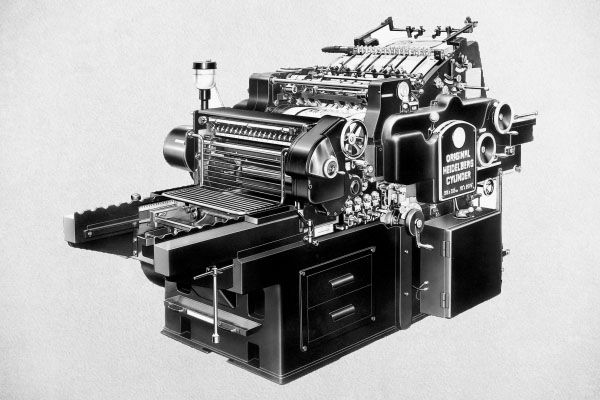

Hot Foil Stamping Attachment for Heidelberg Cylinder Letterpress

Heidelberg Cylinder Letterpress, a testament to timeless engineering, continues to captivate the printing world with its enduring strength and performance. Previously synonymous with letterpress printing, Heidelberg Cylinders are now being transformed into versatile machines, optimized for stamping and dye-cutting processes worldwide.

Unlocking the Potential:

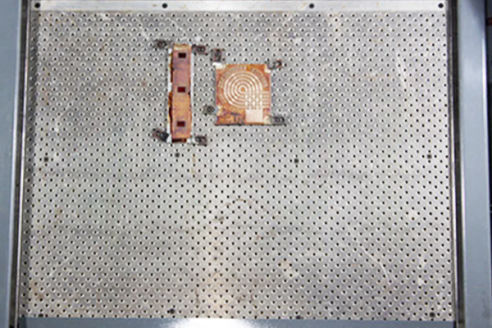

One of the most significant advantages of converting a letterpress machine into a Hot Foil Attachment Machine is its ability to run 16 foil strips, each as narrow as 10mm, in a single job. This empowers you to effortlessly explore the world of holography, making it easy, practical, and cost-effective.